6 WAYS TO MAXIMIZE THE BENEFITS OF FLEXIBLE CHARGING FOR CLASS 3 FORKLIFT TRUCKS

In the fast-paced world of material handling, every minute counts. When it comes to forklift operations, minimizing downtime and maximizing efficiency is crucial. One key area where businesses can make significant gains is in how they manage and charge their forklift batteries. By streamlining the charging process and selecting the right battery and charger technology, companies can reduce maintenance time, free up valuable space, and lower operational costs.

Here are six methods to help you get the most out of your Class 3 forklift trucks. As always, be sure to follow the manufacturer’s guidelines for battery charging, care and handling, and direct any questions to your battery professional.

1. OPT FOR POWERFUL TPPL TECHNOLOGY

Thin Plate Pure Lead (TPPL) is a proven and popular technology for forklift batteries. By reducing the thickness of plates and increasing their number, TPPL batteries have a more reactive surface area - delivering greater power output and enhanced performance versus traditional lead acid batteries.

The pure lead composition of the plates also minimizes electrical resistance to bolster charging speed and reduce corrosion to extend battery life. NexSys® TPPL batteries are maintenance-free, require no water topping-up, and can be fast charged in under 2 hours* without the need for long equalization - making them an excellent choice for light to medium duty applications.

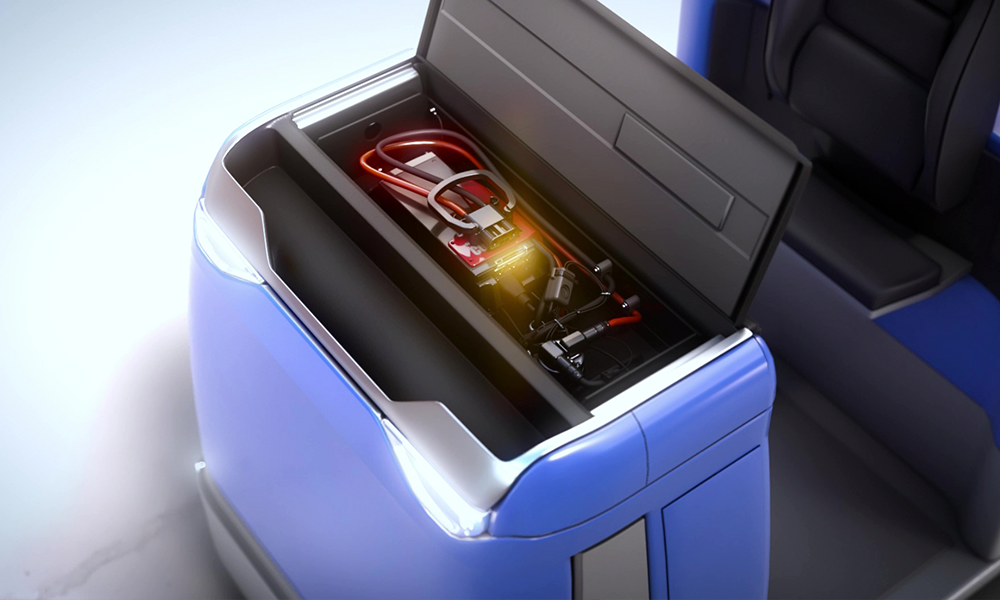

2. EMPOWER YOUR OPERATIONS WITH AN ONBOARD CHARGER

Onboard charging provides complete flexibility for forklift operators. By enabling charging at virtually any location from a nearby AC socket, it eliminates the need for trips to a dedicated charging station, saving time and reducing operational disruption. Moreover, onboard chargers can help businesses save floorspace and the cost associated with dedicated battery charging areas.

3. CHARGE SMARTER WITH OPPORTUNITY CHARGING

Similar to lithium-ion batteries, TPPL batteries are designed to be “opportunity charged” during breaks, shift changes and other periods of non-use. Frequent opportunity charging can significantly extend the life of your TPPL batteries. By avoiding deep discharges and simply “plugging-in” to the nearest AC outlet during breaks for charging, you can keep your forklifts running longer without the need for battery changes. When performed correctly, opportunity charging can boost a battery’s energy throughput to as much as 160% of its nominal capacity – keeping your equipment running through multiple daily shifts.

4. BOOST EFFICIENCY WITH HIGH-SPEED CHARGING

Opportunity charging during breaks or between shifts is an efficient way to keep your forklifts in operation with minimal downtime. The combination of NexSys® TPPL batteries and fast-charge capable onboard chargers, ensures rapid recharges to keep your equipment powered-up - leading to greater productivity and reduced idle time.

5. OPTIMIZE PERFORMANCE WITH THE RIGHT POWER SOLUTION

EnerSys® offers a comprehensive power solution tailored for Class 3 forklift trucks.

The NexSys® COMpact smart, onboard charger when paired with NexSys® TPPL technology creates a powerful all-in-one system. The onboard charger fits seamlessly onto a wide range of NexSys® TPPL batteries for Class 3 equipment, with high-efficiency performance that ensures safe and fast recharges. This integrated approach maximizes productivity, keeping your forklifts running at peak performance with minimal downtime.

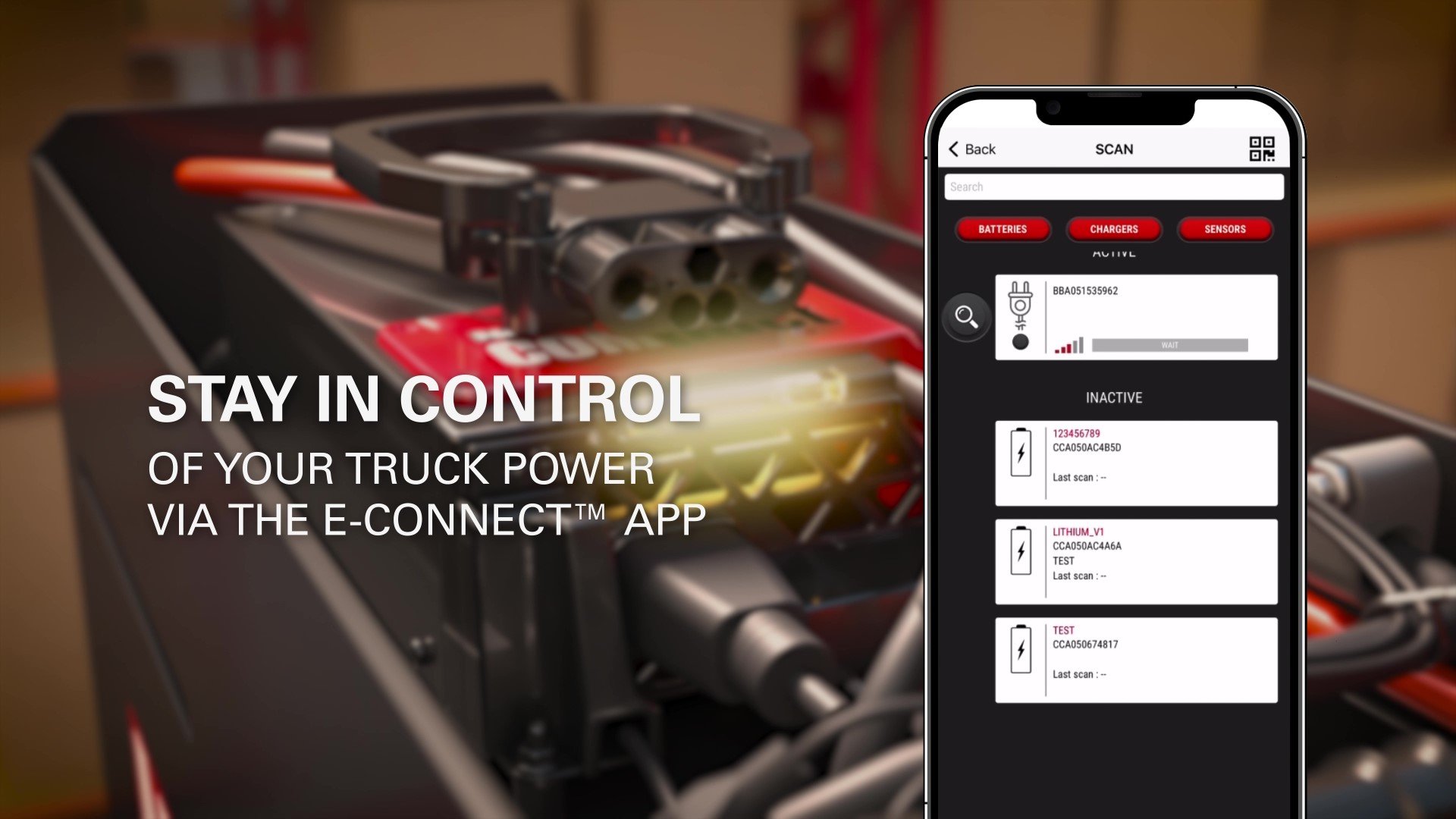

6. STAY AHEAD WITH PROACTIVE MONITORING

Keeping a close eye on your batteries and chargers is essential for optimizing performance. The NexSys® COMpact onboard solution includes built-in monitoring devices that provide real-time data and alerts to help you manage and protect your equipment. With features like a low voltage alarm (LVA), an embedded Wi-iQ® monitoring device to detect misuse of the battery and Bluetooth connectivity, you can use the EnerSys® E Connect™ mobile app to monitor your fleet's battery health and prevent potential equipment failures.

By implementing these six methods, you can ensure that your Class 3 forklift trucks operate at maximum efficiency, with minimal disruption to your workflow.

For more information on the NexSys® COMpact system, contact your local EnerSys® Sales Representative.

*Complete full recharge will take approximately 4 hours, once per week. Subject to charging rate

NexSys® COMpact Onboard Charger

Power-up productivity. Anytime, anywhere